Basic Info

Model No.: ZD-910

Additional Info

Productivity: 30 Sets Per Month

Place of Origin: China

Supply Ability: 30 Sets Per Month

Certificate: CE, ISO, SGS

Product Description

Model NO.: ZD-910

Color: as You Require

Size: 7.3m*1.1m*1.4m

Type: Tile Making Machine

Speed: 10-15m/Min

Raw Material: PPGI/Gi

Thickness of Panel: 0.2mm-0.9mm

Forming Stations: 16, According Profiles

Drive: by 1 Inch Chain

Shaft of Roll Forming Machine: 70mm Solid, 45# Steel

Rollers of Roll Forming Machine: 45# Steel with Heat Treatment

Trademark: Cangzhou Zhongde

Transport Package: as You Require

Specification: ISO9001

Origin: China

HS Code: 8404101000

ZD-910 Color Steel Roll Forming Making Machine

Our Production

1. Brief Description

This machine is used to produce roof panels, the raw material is glazed steel coils, or galvanized steel coils. It imitates the classical Chinese roof tiles, but much more cheaper and stronger than glazed ceremic tiles.

2. Production Flow of Colored Steel Roof Tile Roll Forming Machine

Uncoiling-Material Feeding into Roll Forming Machine-Roll Forming Length Measuring-Automatic Cutting Products- Receiving

1) Manual Uncoiler

The bearing weight is usually 5 tons. We can provide bigger ones according

to customers' actual needs. This uncoiler is used to uncoiling the raw material coils.

2) Material Feeding Platform

The coil after uncoiling will go into the roll forming body throught this device. It can keep the plate well-leveled.

3) roll forming machine

The flat sheet will be formed many defferent patterns after roll forming. Each model has it own design of rollers.

4)Automatic cutting

After making the step, the sheet will be cut automatically according to the setted length. The system includes computer control cabinet, encoder, hydraulic station, step-forming device and cutting device.

5)Products Receiving Tables

They are used to receive the finished products.

Our Service

We have professional team to make different kinds of roll forming machines for our customers, from designing, processing, assembling, debugging, delivery.

Spare parts

We can send our technicians to customer's factory for installation, and teach customer's workers how to use the machines. If there is any problems happened to the machine, we will provide solution at once. Hope we could establish win-win business relations in the soon future!

Andwe provide the technical support for whole life. Meanwhile, if any parts go broken and not artificial damage, we will send you new ones for free.

When need the technician to go abroad, we will arrange the technician.

But the buyer should take all the cost, including Visa, Roundtrip ticket, suitable accommodation and pay the service fee to the technician with $150/days

| Technical parameters: | |||

| 1 | Name of commodity & specification | glazed tile roll forming machine | |

| 2 | Main motor power | 4kw, 3 phase | |

| 3 | Hydraulic motor power | 3kw | |

| 4 | Hydraulic Pressure | 10-12MPa | |

| 5 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) | |

| 6 | Control System | PLC Delta Inverter | |

| 7 | Main Frame | 300mm H-Beam or 350mm | |

| 8 | Backboard Thickness | 14mm | |

| 9 | Chain Size | 20mm | |

| 10 | Feeding Material | color steel coils | |

| 11 | Feeding Thickness | 0.25-0.4mm | |

| 12 | Feeding Width | 1100mm | |

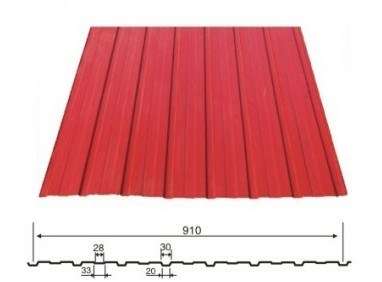

| 13 | Effective width | 910mm | |

| 14 | Productivity | 8-12m/min | |

| 15 | Roll Station | 14 roll steps(according to different design) | |

| 16 | Roller Diameter | 70mm(depend on different design) | |

| 17 | Roller material | 45# steel | |

| 18 | Cutter material | Cr12 , quenched | |

| 19 | Cr-Plating Size | 0.05mm | |

| 20 | Overall Size | 7500×1400×1500mm | |

| 21 | Total Weight | 4.0T | |

| 22 | Components | Manual Uncoiler-------------------1 set | |

| Guiding Platform------------------1 set | |||

| Coil Strip Leveler------------------1 set | |||

| Main Machine of Roll Forming------1 set | |||

| Electric-Motor---------------------1 set | |||

| Cutting Device--------------------1 set | |||

| Hydraulic Station------------------1 set | |||

| PLC Control-----------------------1 set | |||

| Supporter Table-------------------1 set | |||

| 23 | Workflow | Manual decoiling----feeding and guiding----roll forming----cut to length----run out table | |

| 24 | Package | nude in the container | |

| 25 | Minimum order quantity | 1 set | |

| 26 | Payment terms | T/T(30% T/T pay in advance, the remaining 70% pay before ship) | |

| 27 | Delivery time | 30 working days later after receiving the deposit | |

| All technical parameters can be changed, according to user's need. | |||

Product Categories : Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine