Basic Info

Model No.: steel door frame roll forming machine

Additional Info

Productivity: 40sets Per Month

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO

Product Description

Steel Door Frame Roll Forming Machine

The door frame we are talking that is interior door frame with hinge and lock pocket.Our Door Frame Roll Forming Machine,it is customized design.Different designs can be cusotmized as your request.Common thickness of door frame is 0.8-1.2mm,including hinge punching,lockIf you are interested in our machine.

Door frame forming machine is automatic machine,with hinge punching and lock pocket punching.The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously

We would ask you some questions first.

1) Do you have an idea design you need?Including measurement.If pls tell me where are you from.So we can send you some popular designs at your place.

2) What is material thickness u use?Max and Min?

3) What is hardness of material?Is it standard?Or full hard?

4) What is voltage of machine u need?380V,50HZ?220V,60HZ?OR 415v,50HZ?We can make is as your request.

Maybe you have some concern about our machine.

3sets punching are required,Hinge holes punching,lock pocket and edge cutting for joint.Common thickness:0.8-1.3mm

Different opitions for your reference:some customer use 45 degree cutting then do welding.Another is by edge cutting.

87eb58a9c11fc6f734511c65c0.jpg" title="door frame forming machine" alt="door frame forming machine" />

0f9831cbb805759d3daa92f801.jpg" title="door frame forming machine" alt="door frame forming machine" />

pecifications

| 1. | Power requirement | Type | 380v/3ph/50hz | |

| | | Main Motor power | 11kw | |

| | | Cutter power | 5.5kw | |

| 2. | Forming speed(m/min) | 15m/min max | Not include the time of cutting | |

| 3. | Forming stations | 16 stations | | |

| 4. | Thickness of Mild steel | 1mm-1.2mm | | |

| 5. | Material of rollers | CR15 | | |

| 6. | Thickness of structure | 20mm | | |

| 7 | Forming shaft diameter(mm) | 70 | | |

| 8 | Drive | Gear | | |

| 9 | Type of cutting | Hydraulic cutting | | |

| 10. | Control system | PLC and inverter control | | |

| 11. | Install dimension(depend on the final design) | 9.8m×0.85m×1.2m | Without panel length | |

| 12. | Total weight (Approx) | 4.5T | Depend on final design | |

| 13. | Screen | Text screen /touch screen | ||

The advantages of Metal Door Frame Roll Forming Machine are as follows:

1.Accuracy Profile

2.Stable

3.Easy operation, low maintenance cost

4.Beautiful appearance.

5.Customorized for any size you want

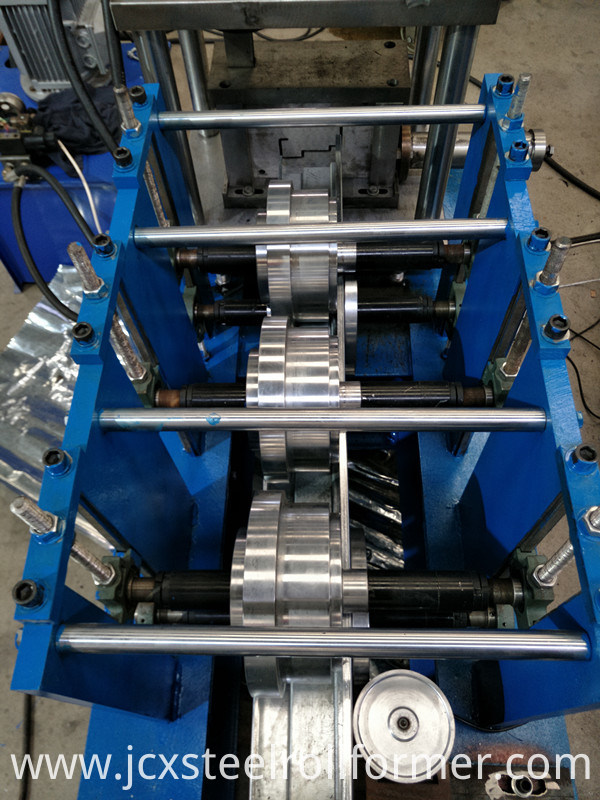

2.Detailed Images of metal door frame Roll Forming Machine

Machine Parts

1) Metal door frame roll forming machine feeding guide

Original: China

2) Metal door frame roll forming machine rollers

Original: China

Rollers manufactured from high quality bearing steel GCr15, CNC lathes, Heat Treatment.

with black treatment or Hard-Chrome Coating for options.

With feeding material guide, body framemade from 400# H type steel by welding

3) Metal door frame roll forming machine post cutter

Original: China

4) Metal door frame roll forming machine product show

Original: China

5) Metal door frame roll forming machine decoiler

Original: China

ManualDecoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 3Ton

With 3 tons hydraulic decoiler for option

6) Metal door frame roll forming machine exit rack

Original: China

Un-powered,3 meters long ,one unit

Other detailes of metal door frame roll forming machine

Suitable for material with thickness 0.8-1.5 mm

Shafts manufactured from 45#,Main shaft diameter=φ75mm,precision machined

Motor driving,Gear chain transmission, 20 rollers to form.

Main motor=11KW , Frequency speed control. Forming speed approx.12-15m/min

PLC Control System (Touch screenbrand:German Schneider Electric/Taiwan WEINVIEW,

Inverter brand:Finland VOCAN/Taiwan DELTA/ALPHA,Encoder brand:Japan Koyo/OMRON)

Combined with: PLC, Inverter, TouchScreen, Encoder, etc

Cut-to-lengthtolerance≤±2 mm

Control Voltage 24V

User's manualin English

After-sale service of metal door frame roll forming machine

1. The warranty of metal door frame roll forming machine

is one year after the client receives the machine.

Within the one year, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories with extra cost.

Terms of trade

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 45 workdays

3. Port of loading: port of tianjin

4. Type of payment: by T/T or by L/C

5. Export: Australia, UK, Ireland, Mexico, Brazil ,Israel ,Dubai, Russia ,India, Taiwan, Singapore,

Malaysia ,Thailand, Philippines, Myanmar ,Vietnam, South Africa, Mozambique,

Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.

Product Categories : Door Frame Roll Forming Machine