Basic Info

Model No.: 2inch

Tile Type: Glazed Steel

Certification: SGS, CE, ISO, Other

Condition: New

Customized: Customized

Usage: Roof, Floor, Other

Transmission Method: Hydraulic Pressure

Name: Steel Decking Sheet Forming Machine For Commercial Building

Model No.: 2 Inch, 3 Inch

Production Speed: 10-15m/min

Control System: By PLC

Warranty: 15 Months

Cutting System: Hydraulic

Power(W): 22KW

Delivery Time: 45 Working Days

After-sales Service: Overseas Available

Voltage: 380V-50HZ-3P Or As Required

Additional Info

Packaging: Plastic package outside the floor deck roll forming machine, make coil inside in case the roller and shaft got rusty.

Productivity: 30 Sets Per Month

Brand: JCX

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 30 Sets Per Month

Certificate: ISO9001: 2000, CE, SGS

HS Code: 845221000

Port: Tianjin, China

Product Description

Floor Decking sheet roll forming machines have been designed for the production of various types of metal decks which are usually applied for building and floor industries, and sometimes for bridge construction as well. The most popular steel decks produced by our metal deck Roll Forming Machine are currently used in the industiral applications as following:

Composite metal deck: The composite metal decks have embossments in the vertical ribs designed to interlock with concrete slabs, creating a reinforced concrete slab to develop a composite floor system.

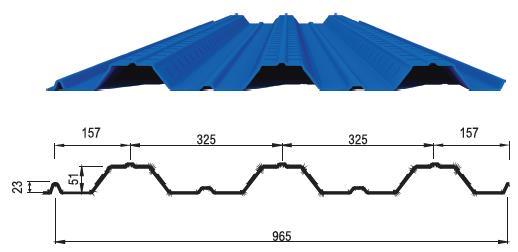

1.1 Feeding width: 1250mm

1.2 Effective width: 1025mm

1.3 Material thickness: 0.8-1.5mm

2. Process flow: Decoiling--feeding---forming---cutting---production

3. Manual Decoiler:

3.1 Material coil inner diameter: 450mm-700mm

3.2 Max coil width: 1200mm

3.3 Carrying capacity: 5T

4. Forming Device:

4.1 Number of forming steps: 24 steps

4.2 Shaft material: 45# steel with harden treatment, outer diameter 90mm

4.3 Roller material: 45# steel

4.4 Main motor power: 11kw(2sets)

4.5 Forming speed: 12-15m/min

4.6 Voltage: 380V/50Hz/3 phase or as your request

5. Cutting Device:

5.1 hydraulic cutter

5.2 blade, puncher and mold material: Cr12 steel with quenched treated 60-62C

5.3 cutting system: Advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor.

6. Controlling Device:

6.1 screen: 5.7 inch Taida screen from Taiwan

6.2 PLC: Taida DVP14ES from Taiwan

6.3 coder: Japanese Omron E6C2

7. Hydraulic:

7.1 Advanced hydraulic system from Taiwan

7.2 Power: 4kw

8. Simple output frame: Simple frame weld bu #8 U bar, 1 PCS of 3m

Product Categories : Composite Floor Decking Sheet Roll Forming Machine > 2 Inch Decking Sheet Forming Machine