Basic Info

Model No.: standinig seam roof machine

Tile Type: Colored Steel

Certification: SGS, CE

Condition: New

Customized: Customized

Usage: Roof

Additional Info

Packaging: standard packing

Productivity: 40sets Per Month

Transportation: Ocean,Land

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO

HS Code: 8455221000

Port: Tianjin

Product Description

Self lock roof forming machine

The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously.

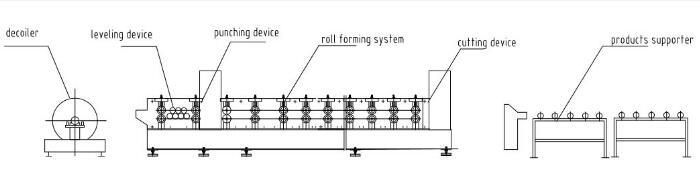

self-Lock standing seam Roofing Panel is used a lot in Ghana.Our self-lock standing seam roof forming machine is composed of Manual Decoiler,main forming machine,automatic cutting.

Our self locking forming machine can be used a workshop.

Specialized manufacturer of Roll Forming Machine,different designs can be customized as your request.

specialized manufacturer 3 Inch Decking Sheet Forming Machine 2 Inch Decking Sheet Forming Machine Composite Floor Decking Sheet Roll Forming Machine Bottom Shutters Profile Forming Machine Door Guide Rail Forming Machine

| Technical Data of standing seam machine | ||

| 1 | Material Width | 32&24inch |

| 2 | Effective Width | 220-530mm |

| 3 | Thickness of Coil | 0.5-0.8mm |

| 4 | Application | standing seam roof panel |

| 5 | Estimated Dimension | 6500mmX1100mmX1200mm |

| 6 | Total Weight | 4.9 Tons |

| 7 | Main Power | 4+3KW |

| 8 | Decoiler | Manual or Hydraulic Decoiler |

| 9 | Inner Diameter | 508mm |

| 10 | Outer Diameter | 600 |

| 11 | Loading Weight | 4-5T |

| 12 | Forming Speed | 0-11m/min |

| 13 | Forming Station | 16 stations |

| 14 | Bracket | Welded with 36 # I-steel |

| 15 | Material of Shaft | High Grade forged 45# Steel with 1st Rough Finished and then 2th Refined Finished |

| 16 | Diameter of the Roll | 60mm |

| 17 | Material of Roller | High Quality Cr12 Quenched HRC58-62 ° |

| 18 | Processing Technology | Rough Processing ---Refined Processing--Hard Chromium Plating. |

| 19 | Material of Rack | Complete Welded Structure of A3 Steel Plate 20 mm Thickness |

| 20 | Transmission | Chain driving |

| 21 | Material of cutting blade | Cr12 with Quenched Treatment 60-62 ° |

| 22 | Cutting system | Hydraulic Stop or Tracking Cutting |

| 23 | Voltage | 380V/50HZ/3 Phase or as Customer Require |

3.The production process of standing seam roll forming machine

Decoiler→Flating→Feeding →Forming→Cut to length→Colletion

(finish goods)

1. Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also

train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary

things.

2. After Service

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it for free in one year.

Product Categories : Standing Seam Roof Roll Forming Machine > Nail Strip Standing Seam Forming Machine