Basic Info

Tile Type: Colored Steel

Certification: SGS, CE, ISO

Condition: New

Customized: Customized

Usage: Roof, Wall, Other

Transmission Method: Electric

Suitable Material: Ppgi,gi,aluminum,alu-zinc

Diameter Of Shaft: 70mm

Driving Of Gutter Machine: By Chain

Main Power Of Machine: 5.5kw

Color Of Machine: Blue Or As Your Request

Sizes Of Gutter: 6inch

Voltage Of Machine: According To Customers′ Request

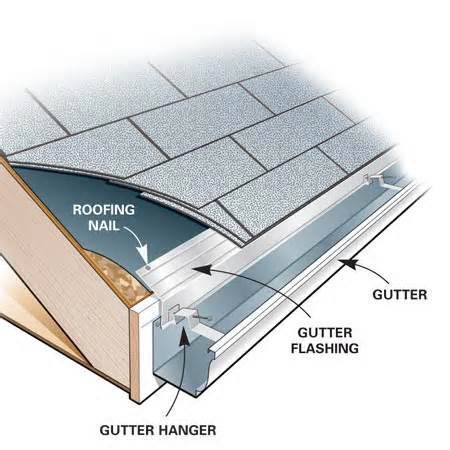

Application Of Gutter: Rain Water Goods

Structure Of Machine: 350H Beam

Additional Info

Packaging: plastic file covered

Productivity: 40sets Per Month

Brand: jcx

Transportation: Ocean,Land

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE

HS Code: 8455221000

Port: Tianjin

Product Description

round downspout gutter sheet Roll Forming Machine

Our round downspout gutter sheet roll forming machine is high capacity in making this rainwater gutter, it is composed of Manual Decoiler,forming part,automatic cutting.The common raw material is aluminum,ppgi,copper.Usually half round gutter match with round downpipe,k style gutter match with square downpipe.Our downpie gutter machine can be customized as your request

The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously.

ff80d1f0fbf971b4b923841cc4.jpg" title="Square Gutter Forming Machine" alt="Square Gutter Forming Machine" />

TECHNICAL PARAMETERS

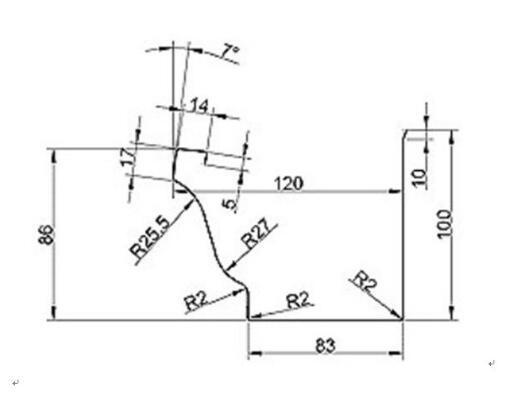

1.gutter specification:

1)Material:hot dipped galvanized coil,galvalume steel

2)Thickness of material:0.35-0.7mm

3)Yield strength:235-340mpa

4)Width of material:

5)Sizes of imposing:

Main technical conditions of the forming line:

Temperature:-10ºC~35ºC

Voltage:380V,50HZ,3P(or according to customer request)

Air pressure:0.6~1.2Mpa

Total Power:≈21kw

Color:

Production capacity:0-50meters/min(without punching,no stop cutting)

0-30meters/min(with punching,no stop cutting)

Dimension (L*W*H): L≈ 5.3 m, W≈ 0.9 m, H≈ 1.5 m

Specification of the shipping container:(the number is pre-estimated ≈, final data should be confirmed in two weeks before delivery.)

| Container | 20FT | 40FT | 40HQ |

| Number | 1 |

|

|

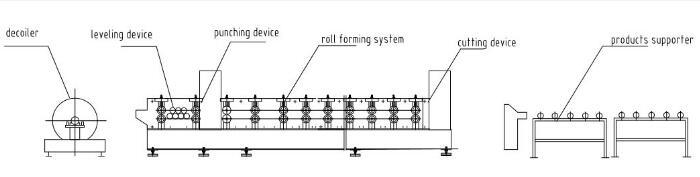

3. Flow Chart of roll forming machine:

4.Main components:

| No. | Components Name | Unit Set/Pcs | Marks |

| 1 | Two head Manual de-coiler | 1 | |

| 2 | Feeder | 1 | |

| 3 | Roll Forming Machine | 1 | |

| 4 | Punching system | 1 | |

| 5 | Electrical control system | 1 | |

| 6 | Hydraulic Guillotine | 1 | |

| 7 | Powered Receiving table | 1 | |

| 8 | Spare parts | 1 | |

| 9 | Technical Manual | 1 | |

5.Photos of Machine:

fb0891ad9b7ba71a47fb305135.jpg" width="500" height="566" title="gutter forming machine" alt="gutter forming machine" />

6.Technology parameters:

The weight of machine is about 3.5tons

The total dimension of machine:5300(L)*900(W)*1500mm(H)

6.1Two head head Manual uncoiler: 1SET

Capacity of uncoiler:2-3tons

Expansion of segment:Manual

Rotation of segment:ManualNumber of segment:4

Approximate size:Length:2.3m width:1.1m height:1.5m

6.2 Feeding&levelling:

Entrance and adjustable wheel: 2rolls

Qty: 1

6.3Main forming machine:

It adopts separate wall structure with gear box transmission.The machine base is made by welded steel with destressing treatment.

Coil thickness:0.35-0.8mm

Main motor type: 3 phase asynchronous motor

Main motor power: 15KW

Forming speed: 0-50m/min(without punching),0-30m/min(with punching)

Approx. 14 groups rollers

Roller : Roller Material is forged Cr12, HRC58-62

Shaft: Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product. Diameter of main shaft: ø60mm

Material of shaft:40cr,quenching HRC45

Transmission type: by chain

Qty: 1

Power cutting:3kw

6.4Hydraulic System:

Material of blade: Cr12Mov(HRC58-62)

Length measuring: Automatic encoder length measuring

(Encoder Brand:Omron)

Power of cutting:5kw

Punching die:adopt cell structure design,the die is adjustable.It has features like long life,easy replacement and repairing.

Spare parts(free)

| No. | Name | Quantity | Country |

| 1 | Spacer | Several | China |

| 2 | Cylinder seal | several | China |

| 3 | Fuses | 4pcs | China |

| 4 | Control Button | 2pcs | China |

| 5 | Sensor | 4pcs | China |

| 6 | Hook spanner | 2pcs | China |

| 7 | Encoder | 2pcs | China |

Our company has been built over 15 years,it is located in north of China,near from Tianjin port,we have strong selling team and exquisite technology

Product Categories : Rain Gutter Roll Forming Machine > K Gutter Roll Forming Machine