Basic Info

Model No.: pbr

Additional Info

Productivity: 40sets Per Month

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO

Product Description

Pbr Panel Roll Forming Machine

pbr panel are used a lot in USA and North America:

Roll Forming Machine has many cost advantages over brake forming and preformed panels. If you are not familiar with what roll forming can do for your bottom line, here are just a few of the savings you can expect...·

No Expensive Shipping and Crating of Long Panels

(Have coils delivered right to your shop or jobsite

No Panel Shipping Damage and Extensive Delays

(Just try to order one replacement panel from the factory)

Less Labor and Waste

(Run your panels to the exact length without time and material waste)

Work On Your Own Schedule - Not The Factory's

(When roof is ready -- just run your panels)

Form Perfect Panels To Any Length

(Form long panels at the site or on the roof without crating problems)

· specialized manufacturer of

Wall Panel Roof Forming Machine

K Gutter Roll Forming Machine

Half Round Gutter Roll Forming Machine

Rain Gutter Roll Forming Machine

Auto Roll Forming Machine Stacker

Steel Slitting Line

pbr panel roll forming machine photos

1. Detailed Parameters of roof sheet roll forming machine

| No | ||

| 1 | Suitable Material | Colored Steel plate, Galvanized Board, Aluminum Plate |

| 2 | Width of the raw material | 1000mm |

| 3 | Rows of rollers | 14 rows |

| 4 | Appearance size | 6.8*1.4*1.5m |

| 5 | Total power | 3.7 kw |

| 6 | Thickness of raw material | 0.2-0.8mm |

| 7 | Productivity | 3-4m/min |

| 8 | Diameter of shaft | ¢70mm |

| 9 | Voltage | 380V 50Hz 3phases |

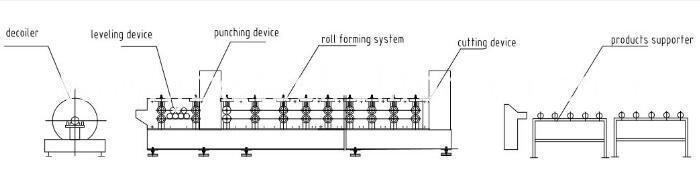

2. The Chart of Process Flow of roof panel forming machine

2.1. Components and Technical Specification

| No | Technical Specification | |

| 1 | Manual Uncoiler | Usage: It is used to support the steel coil and uncoil it in a turntable way. The steel coil is uncoiled by hand. Loading capacity:5T Inner diameter: 500-508mm |

| 2 | Feeding Table | Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. |

| 3 | Main Roll Forming Machine | Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. |

| 4 | Shearing Mechanism | It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12,quenching treatment |

| 5 | Press Form | Press Form Material of blades: Cr12,quenching treatment |

| 6 | Hydraulic System | Power:4kw,Hydraulic oil: 40# Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job. |

| 7 | Computer Control Cabinet | The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use PLC |

| 8 | Spare parts | one box |

3. Packing Method

Main machine is nude; the computer control box is packed by carton box

4. Transportation

All machines need one 40 feet container to hold

5. Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment

6. Delivery Time

Within 30 days after receiving deposit.

Warranty Two years, and we will provide technical support for whole life of the equipment.

If the plate with a coating,the coating should be consistent with coating inspection standards of the relevant color-coated,should not have skin off,so as not to effect quality of roll forming.

If the material is galvanized steel,the galvanized should be consistent with the relevant testing standards of the galvanized steel,should not have zinc layer off,so as not to effect the quality of roll forming.

Looking for ideal R Roof Panel Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Pbr Panel Forming Machine are quality guaranteed. We are China Origin Factory of Usa R Panel Roll Former. If you have any question, please feel free to contact us.

Product Categories : Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine