Basic Info

Model No.: roll forming machine

Additional Info

Productivity: 40sets Per Month

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO

Product Description

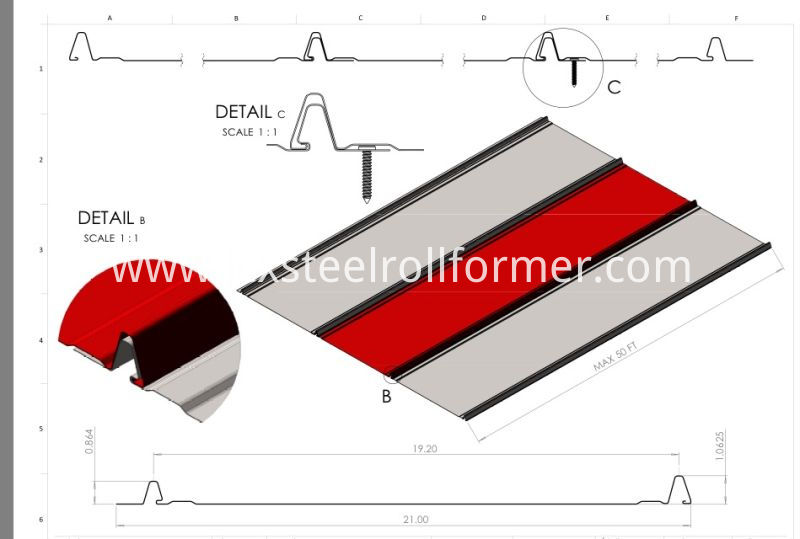

Equipment for standing seam roof

snap locking is a new trend for now.

This design no need cliper and seamer,fixed by screw.

the standing seam roof panels have a concealed fxing or seaming method by turning up the edges of two adjacent panels, and then folding or interlocking them. In this way, the seaming or fixing parts are invisible, and therefore sometimes we called the panels concealed fixing panels! The machine got its name as concealed fixing standing seam Roll Forming Machine accordingly!

Machine designers always build the hydraulic pressing between roll forming part and hydraulic cutter so that the depth, distance and quantities of steps can be adjustable and clients can change any time throught the touch screen on PLC control box.

we supply Roof Panel Roll Forming Machine Cz Purlin Roll Forming Machine High Way Crash Barrier Roll Forming Machine Light Gauge Framing Machine Roller Shutter Door Forming Machine Double Layer Roll Forming Machine

935ac8a908d41d8344e031da70.jpg" alt=" />

| Technical Datas clicklock standing seam roof machine | ||

| 1 | Material Width | 32&24inch |

| 2 | Effective Width | 220-530mm |

| 3 | Thickness of Coil | 0.5-0.8mm |

| 4 | Application | standing seam roof panel |

| 5 | Estimated Dimension | 6500mmX1100mmX1200mm |

| 6 | Total Weight | 4.9 Tons |

| 7 | Main Power | 4+3KW |

| 8 | Decoiler | Manual or Hydraulic Decoiler |

| 9 | Inner Diameter | 508mm |

| 10 | Outer Diameter | 600 |

| 11 | Loading Weight | 4-5T |

| 12 | Forming Speed | 0-11m/min |

| 13 | Forming Station | 16 stations |

| 14 | Bracket | Welded with 36 # I-steel |

| 15 | Material of Shaft | High Grade forged 45# Steel with 1st Rough Finished and then 2th Refined Finished |

| 16 | Diameter of the Roll | 60mm |

| 17 | Material of Roller | High Quality Cr12 Quenched HRC58-62 ° |

| 18 | Processing Technology | Rough Processing ---Refined Processing--Hard Chromium Plating. |

| 19 | Material of Rack | Complete Welded Structure of A3 Steel Plate 20 mm Thickness |

| 20 | Transmission | Chain driving |

| 21 | Material of cutting blade | Cr12 with Quenched Treatment 60-62 ° |

| 22 | Cutting system | Hydraulic Stop or Tracking Cutting |

| 23 | Voltage | 380V/50HZ/3 Phase or as Customer Require |

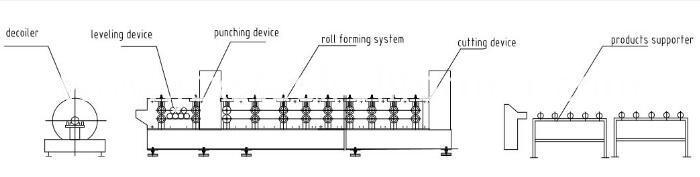

3.The production process

Decoiler→Flating→Feeding →Forming→Cut to length→Colletion

(finish goods)

Product Categories : Standing Seam Roof Roll Forming Machine > Nail Strip Standing Seam Forming Machine