Basic Info

Model No.: Galvanized Steel Sheet Roofing Tile Making Machine

Tile Type: Glazed Steel

Certification: SGS, CE, ISO, Other

Condition: New

Customized: Customized

Usage: Roof, Wall, Steel Sheet Roofing Tile Making Machine

Transmission Method: Electric

Name: Galvanized Steel Sheet Roofing Tile Making Machine

RAW MATERIAL: PPGI, GI, Aluminum

Pressing Thickness: 0.3-0.8mm

Width Of Steel Coil: 10000-12500mm

Cutting Type: Hydraulic Guider Pillar Or Plate Welding Cutting Device

Drive By: Chain And Gear

Move By: Hydraulic Motor Or Oil Motor

Forming Stations: 14-18

Control System: By DELTA PLC

Additional Info

Packaging: the whole Wiped Anti Rust Oil, PLC controller covered by foam film;Spare parts and some small parts packed in plastic tooling box;

Productivity: 40sets Per Month

Brand: JCX

Transportation: Ocean,Land

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO, SGS

HS Code: 845221000

Port: Tianjin, China

Product Description

Galvanized Steel Sheet Roofing Tile Making Machine

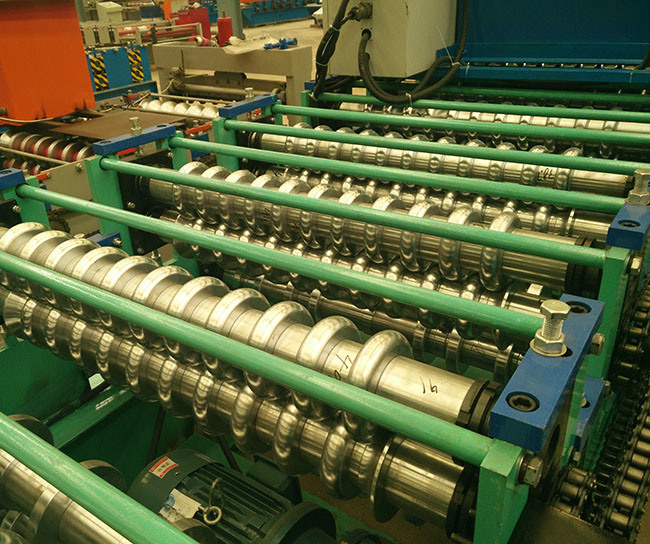

Roller material: High grade NO. 45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm.

Active shaft material: High grade NO. 45 carbon wrought steel at diameter 72mm.

Cutting blade: Cr12 mould steel with quenched treatment.

They are widely used as the roof of garden like factory, hotel, exhibition center, villa, civil construction, etc.

Guiding device:

Adopt guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming system. Can adjust the guiding bar with loosing the fixing bolts to feed sheet in right position. It's fixed structure to make sure can not move easily.

Roll Forming System:

Roll forming system consist of machine frame, transmission system, electrical motor and roll forming system.

A. Machine frame adopts welding structure with shot blasting and painting treatment

B. All rollers material adopt high quality No. 45 steel, with hard chrome coated on surface, all treatment by full CNC machines, to make sure the rollers with good rigidity and precision, and form perfect roofing sheet as per design.

C. All rolling shafts are made by high quality No. 45 steel with quench and temper treatment, so the shafts with good rigidity which could use for long tern without deformation.

D. Rolling shafting supporting structure type is steel wall and welded with the basement together to have rigidity.

E. Cycloidal pin gear speed reducer motor driven, the back/forward roller driven by chain, part of upper/lower rollers driven by gear

F. Adjust the screw bar manually to adjust the distance between upper/lower rollers for difference thickness of sheet.

(Attention: All rolling system has adjusted in our company as a perfect situation, we don't suggest to adjust the rollers at random, if necessary, should adjust by a experienced technician or after train by our engineer. Otherwise will cause the machine can not form a good profile

Cutting device:

A. Adopts post cutting, the cutting blade material is Cr12 with quenched treatment, after cutting, there is no material wasted.

B. Adopts welded frame for good rigidity.

C. The cutting action is droved by the power from hydraulic station which guarantees the procession of the cutting and low noisy, long life.

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job.

The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves.

Power of the oil pump: 3kw

Hydraulic oil: 40#

PLC control system:

Processing precision: Within 1.00mm

PLC is Taiwan Panasonic

Transducer brand is Taiwan taida

The seller should provide Chinese and English language screen

Counter

One counter gauges length, pulses, and decides length.

| Main parameter of Roll Forming Machine: | |

| Suitable to process | Steel plate |

| Width of the plate | 1000mm/1200mm/1250mm |

| Rollers | 15rows |

| Dimensions | 7.8*1.55*1.51m |

| Power | 4kw+4kw |

| Thickness of the plate | 0.3-0.7mm |

| Productivity | 15-20m/min |

| Diameter of the roller | ¢70mm |

| Weight | About 3.4T |

| Voltage | 380V 50Hz 3phase |

839bb179aeb5b83507c4079139.jpg" title="Htb1ey Rkxxxxxcaxpxx760xfxxxa" alt="Htb1ey Rkxxxxxcaxpxx760xfxxxa" />

Product Categories : Roof And Wall Panel Roll Forming Machine > Roof Tile Roll Forming Machine