Basic Info

Model No.: roof panel machine

Additional Info

Productivity: 40sets Per Month

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO

Product Description

Galvanized Roof Tile Roll Forming Machine

Colored coated galvanized roof step tile are produced by glazed tile Roll Forming Machine from high quality prepainted sheets most time apply as roofing on Villas or some residential buildings.

There is only one but key difference between a metal glazed roof tile and a regular metal roof panel: Steps! Generally speaking, a regular metal roof panel with steps is called a metal glazed roof tile! The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously.

specialized manufacturer of Cz Purlin Roll Forming Machine High Way Crash Barrier Roll Forming Machine Light Gauge Framing Machine Roller Shutter Door Forming Machine Double Layer Roll Forming Machine

515b77c5f10c5992cbbd0f172c.jpg" width="454" height="340" title="roof tile roll forming machine" alt="roof tile roll forming machine" />

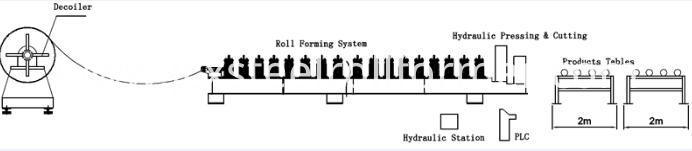

1.Processing flow diagram of aluminum metal roof sheet double layer machine

Manual Decoiler→Feeding material into machine→Roll forming machine→Measure length→Hydraulic cutting→Finished Products

3f5bd5f6210295e968e3f67138.jpg" width="720" height="405" title="roof tile roll forming machine" alt="roof tile roll forming machine" />

2.Technical parameters

| Model number | Metal Roofing Sheet Double Layer Making Roll Forming Manufacturing Machine |

| Rolled material | 0.3-1.0mm thickness, aluminum sheet, galvanized sheet, colored steel sheet and various steel plates |

| Effective width | any roof panel |

| Feeding width | 1000/1200/1250mm |

| Forming steps | up and down layer stations |

| Roller | 45# forged steel, hard chrome plating within 0.05mm |

| Diameter of shaft | 70mm |

| Main motor power | 7.5 kw |

| Pump power | 4kw |

| Sprocket chain | 1 inch |

| Drive type | by chain |

| Cutting Blade | Cr12, heat treatment 60-62°C |

| Frequency Converter | It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

| component | 1 set of manual decoiler,1 set of main roll forming machine,1 set of computer control cabinet,1 set of hydraulic System,1 set of cutting mechanism,1 set of counter,1 set of output table |

| Payment terms | cash,T/T,L/C. |

Remark: Above parameters are standard, we can design and make some change exactly according to your requirements.

Looking for ideal Roof Tile Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Colored Coated Galvanized Tile Forming Machine are quality guaranteed. We are China Origin Factory of Steel Forming Machine. If you have any question, please feel free to contact us.Product Categories : Roof And Wall Panel Roll Forming Machine > Roof Tile Roll Forming Machine