Basic Info

Model No.: JCX_furring

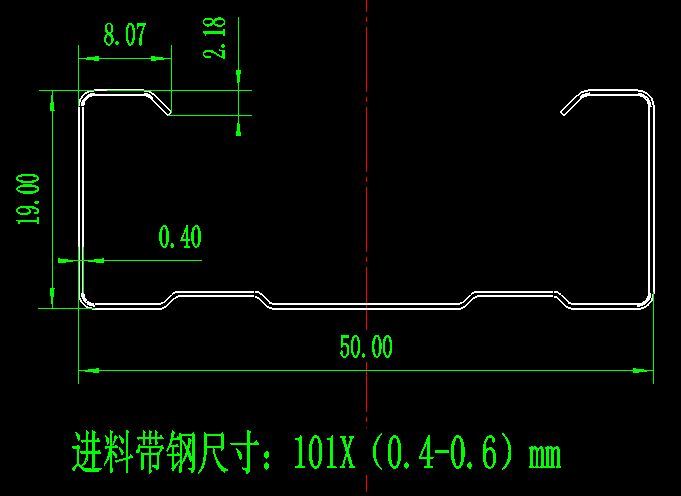

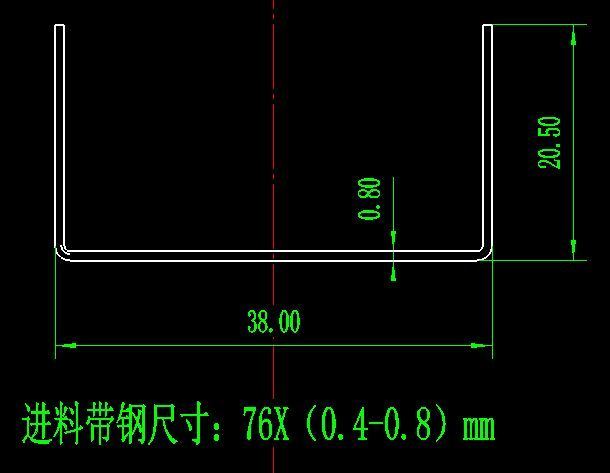

Shaft: 40-60mm

Power: 4+3kw

Speed: 20-30m/min

Cutting: Cr12, Mould Cutting

Additional Info

Packaging: standard seaworthy package

Productivity: 30sets/Month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 30sets/Month

Certificate: CE ISO SGS

HS Code: 84552210

Port: Tianjin

Product Description

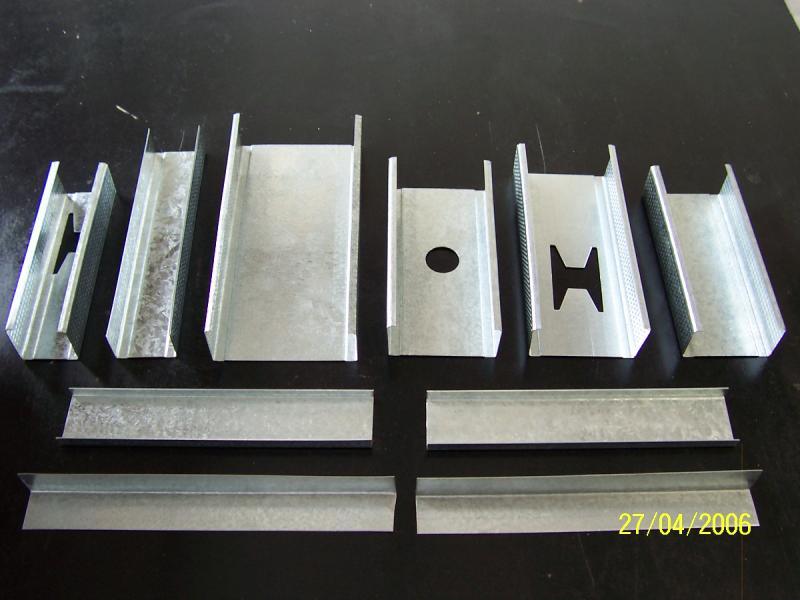

One Machine to make at least Two or more different designs of ceiling channel.

Double Furring Channel Roll Forming Machine For Ceiling share one main frame, two different forming systems to produce different designs ( c/u/omega/t) .

Send us your requirements, let us design the best proposals for you!

Model NO.: double furring

Double Line Ceiling Furring Channel Roll Forming Machine

789119e3495fff7f8e894d8358.jpg" title="174A6996" alt="174A6996" />

1:Our advantageous:

1): Factory direct supply price.

2): We have exported for more than 10 years.

3): Our customer are from about 40 countries.

4): We have the professional research team. We can make the machine according to your requirement.

5): High-end and high-grade design

2.Specification

3.Component

1. Manual De-coiler---1Set

2.Feeding Material Device---1Set

3.Roller Former Device---1Set

4.Hydraulic Cutting Device---1Set

5.Hydraulic station---1Set

6.PLC Control Box

7.Production Racks---1Sets

| Technical parameters: | |||||||

| 1 | Name of commodity & specification | Drywall Galvanized Sheet Light Steel Profiles Metal Stud/Track Roll Forming Machine ud cd uw cw profiles | |||||

| 2 | Main motor power | 4kw, 3 phase | |||||

| 3 | Hydraulic motor power | 3kw | |||||

| 4 | Hydraulic Pressure | 10-12MPa | |||||

| 5 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) | |||||

| 6 | Control System | PLC Delta Inverter | |||||

| 7 | Main Frame | welded steel plate | |||||

| 8 | Backboard Thickness | 20mm | |||||

| 9 | Driving of machine | gear box and chain driving | |||||

| 10 | Feeding Material | color steel coils | |||||

| 11 | Feeding Thickness | 0.3-1.2mm | |||||

| 12 | Feeding Width | 90 | |||||

| 13 | Effective width | according to your request | |||||

| 14 | Productivity | 0-25m/min | |||||

| 15 | Roll Station | 10 | |||||

| 16 | Roller Diameter | 50mm | |||||

| 17 | Roller material | 45# steel | |||||

| 18 | Cutter material | Cr12 , quenched | |||||

| 19 | Cr-Plating Size | 0.05mm | |||||

| 20 | Overall Size | 3600×900×1200mm | |||||

| 21 | Total Weight | 2.7T | |||||

| 22 | Components | Manual Uncoiler-------------------1 set Guiding Platform------------------1 set Coil Strip Leveler------------------1 set Main Machine of Roll Forming------1 set Electric-Motor---------------------1 set Cutting Device--------------------1 set Hydraulic Station------------------1 set PLC Control-----------------------1 set Supporter Table-------------------1 set | |||||

| 23 | Workflow | Manual decoiling----feeding and guiding----roll forming----cut to length----run out table | |||||

| 24 | Package | nude in the container | |||||

| 25 | Minimum order quantity | 1 set | |||||

| 26 | Payment terms | T/T(30% T/T pay in advance, the remaining 70% pay before ship) | |||||

| 27 | Delivery time | 30 working days later after receiving the deposit | |||||

| All technical parameters can be changed, according to user's need. Call us for further information ! 381b1e8954360a665c9c1047a3.jpg" title="Factory Business Card" alt="Factory Business Card" /> | |||||||

Product Categories : Light Gauge Steel Framing Forming Machine > Double Furring Ceiling Roll Forming Machine