Basic Info

Model No.: Corrugation Galvanized Roof Steel Forming Machine

Tile Type: Glazed Steel

Certification: SGS, CE, ISO, Other

Condition: New

Customized: Customized

Usage: Roof, Wall, Other, Metal Roofing And Wall Sheet Machinery

Transmission Method: Hydraulic Pressure

Name: Corrugation Galvanized Roof Steel Forming Machine

Power(KW): 5.5+4kw

Forming Stations: 14-18

Voltage: 380V 50Hz 3phase, Or As Your Request

Pressing Thickness: 0.3-0.8mm

RAW MATERIAL: PPGI, GI, Aluminum

Control System: By PLC And Inverter

Trademark: JCX, OEM, ODM

Structure Of Machine: 350H Beam

Additional Info

Packaging: the whole Wiped Anti Rust Oil, PLC controller covered by foam film; Spare parts and some small parts packed in plastic tooling box;

Productivity: 60sets

Brand: JCX

Transportation: Ocean,Land

Place of Origin: Hebei, China

Supply Ability: 60sets

Certificate: CE, ISO, ISO9001: 2008

HS Code: 8455221000

Port: Tianjin, China

Product Description

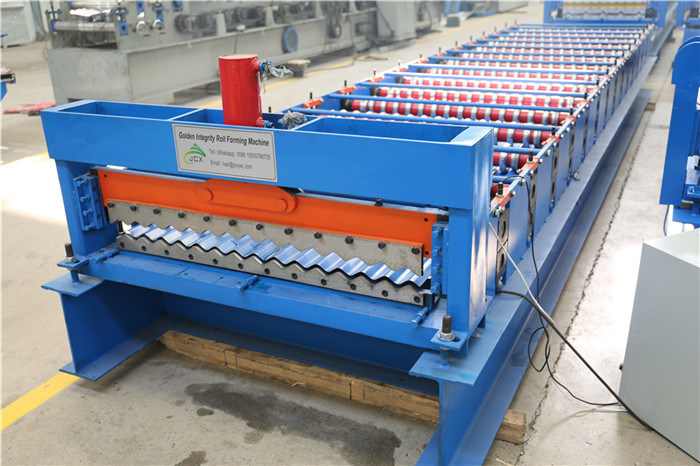

Corrugation Steel Forming Machine-galvanized roof machine

1. Profile drawing:

50e46a6b8395436d9da422fcbc.png" width="700" height="166" title="Coru 762" alt="Coru 762" />

1.2 Effective width: 1000mm

1.3 Material thickness: 0.3-0.8mm

2. Process flow: Decoiling--feeding---forming---cutting---production

46d0d6c9e9ca8b2a5cba34849d.jpg" title="Working Flow" alt="Working Flow" />

3. Manual Decoiler:

3.1 Material coil inner diameter: 450mm-700mm

3.2 Max coil width: 1250mm

3.3 Carrying capacity: 5T

4. Forming Device:

4.1 Number of forming steps: 14 steps

4.2 Shaft material: 45# steel with harden treatment, outer diameter 75mm

4.3 Roller material: 45# steel

4.4 Main motor power: 5.5kw

4.5 Forming speed: 8-10m/min

4.6 Voltage: 380V/50Hz/3 phase

5. Cutting Device:

5.1 hydraulic cutter

5.2 blade, puncher and mold material: Cr12 steel with quenched treated 60-62C

5.3 cutting system: Advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor.

6. Controlling Device:

6.1 screen: 5.7 inch Taida screen from Taiwan

6.2 PLC: Taida DVP14ES from Taiwan

6.3 coder: Japanese Omron E6C2

7. Hydraulic:

7.1 Advanced hydraulic system from Taiwan

7.2 Power: 4kw

8. Simple output frame: Simple frame weld bu #8 U bar, 1 PCS of 3m

| Suitable to process | Steel plate |

| Width of the plate | 1000mm/1200mm/1250mm |

| Rollers | 15rows |

| Dimensions | 8.8*1.55*1.51m |

| Power | 4kw+4kw |

| Thickness of the plate | 0.3-0.7mm |

| Productivity | 8-15m/min |

| Diameter of the roller | ¢75mm |

| Weight | About 3.4T |

| Voltage | 380V 50Hz 3pha |

9. More Machine Details:

3104fa10a82312c3814cb6cb1c.jpg" title="Cold Roll Forming Machine" alt="Cold Roll Forming Machine" />

9. Finished Panels:

36289cfe88e28178fb8bf8d337.jpg" alt=" />

9285e9fd0427ebe0f32c4bcebe.jpg" width="600" height="450" alt=" />1da685fef6d0b4193f10424fb0.jpg" width="600" height="303" alt=" />

Looking for ideal Galvanized Roof Steel Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Corrugation Roof Steel Forming Machine are quality guaranteed. We are China Origin Factory of Corrugation Steel Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Roof And Wall Panel Roll Forming Machine > Corrugated Roof Roll Forming Machine