Basic Info

Model No.: JCX18-26-1060

Additional Info

Productivity: 40sets Per Month

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Product Description

Corrugated iron Roof Forming Machine

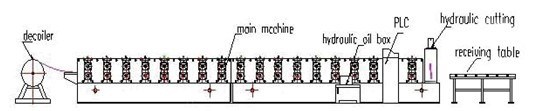

- This machine is made up of Roll Forming Machine,molding press,cutting machine,PLC computer control and hydraulic system

- The machine is stable,no noise,no shake

- Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable, maintenance-free

- cutting machine is characterized by stable driving, easy operation

- hydraulic system use the CDF-10 hydraulic pump, long operating life,no noise

- this machine is applies to roof fortification

Flow chart:

Decoilling the sheet--sheet guilding--film covering--roll forming--measure length--cutting the panel--panel to the supporter

Machine Feature:

1.Precise forming

2. High-solid forming stand guarantees the goods and uniform high quality of final productd

3. The operation automatically minimizes the tolerance of cutting length

Products Feature:

1. A stylish and attractive design, giving the apperance of a traditional roof tile.

2. Resistant to frost, heat,hail and gales; 100% waterproof, due to the lateral run-off channel on each sheet for several models.

3.The raw material can be in different color, with elegant and noble looking. It is widely used as the garden like factory, hotel, exhibition, villa,civil construction etc.

Technical Parameters:

Material Spec: colored steel sheet; galvanized steel sheet

Thickness of coil sheet: 0.3-0.8mm

Main Motor Power: 4 kw

Forming Speed: 10-15m/min

Hydraulic station power: 3kw

Quantity of stand:about 14 or 16 stands

Hydraulic pressure:10-12mpa

controlling system: PLC

Index error of length:10m+2mm

Total weight: about 6 tons

Voltage: 380V 3phase 60 HZ or at buyer's requirement

Material of main equipment

Roller material: high grade NO.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm

Active shaft material: high grade NO.45 carbon wrought steel at Φ 72mm

Cutting blade: Cr12 mould steel with quenched treatment.

Basic Information

Product/Service (We Sell):Roll forming machine,steel glazed tile forming machines,cutting machines,slitting machines,roll forming machinery

Brands:HY Roll forming machine

Number of Employees:101 - 200 People

Trade & Market

Main Markets:North America

South America

Eastern Europe

Southeast Asia

Africa

Oceania

Mid East

Eastern Asia

Western Europe

Central America

Northern Europe

Southern Europe

South America

Eastern Europe

Southeast Asia

Africa

Oceania

Mid East

Eastern Asia

Western Europe

Central America

Northern Europe

Southern Europe

Main Customers:trading company,manufacturer

Total Annual Sales Volume:US$2.5 Million - US$5 Million

Export Percentage:41% - 50%

rest 60% of the total contract value to be paid by T/T after

inspection by buyer in seller's factory while before delivery.

Delivery: 30 working days after receipt of advance payment

Service: we sent technician to your country to fix the machine.

The buyer should bear all the cost including: visa , Roundtrip ticket

and suitable accommodation, also buyer should pay the salary

100USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping feeSales terms

| main parameter of roll forming machine | |

| Suitable to process | Steel plate |

| Width of the plate | 1000mm/1200mm/1250mm |

| Rollers | 9-11rows |

| Dimensions | 5.8*1.55*1.51m |

| Power | 4kw+4kw |

| Thickness of the plate | 0.3-0.7mm |

| Productivity | 8-10m/min |

| Diameter of the roller | ¢ 70mm |

| Weight | About 3.4T |

| Voltage | 380V 50Hz 3phases |

Product Categories : Roof And Wall Panel Roll Forming Machine > Corrugated Roof Roll Forming Machine