Basic Info

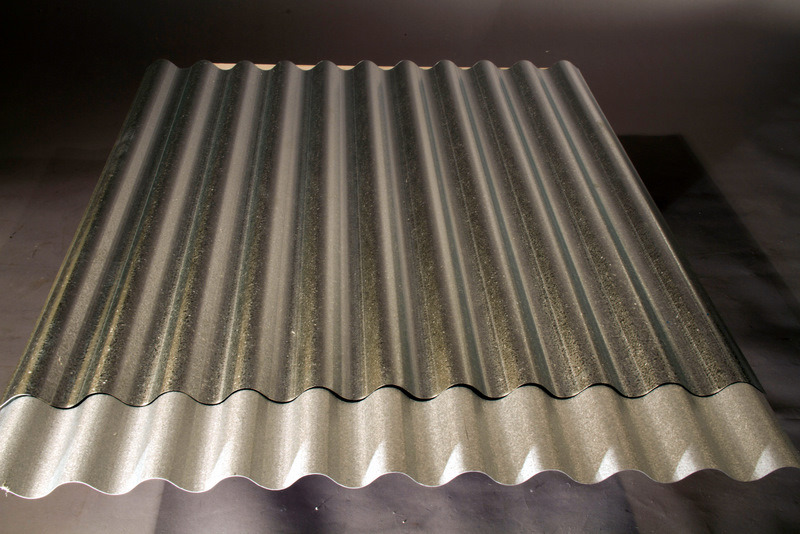

Model No.: corrugated and trapezoidal

Additional Info

Productivity: 40sets Per Month Place of Origin: China Hebei Supply Ability: 40sets Per Month Certificate: CE, ISO

Product Description

Corrugated and Trapezoid Roofing Roll Forming Machine

The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish this action,the machine will run again continuously.No need much labor.

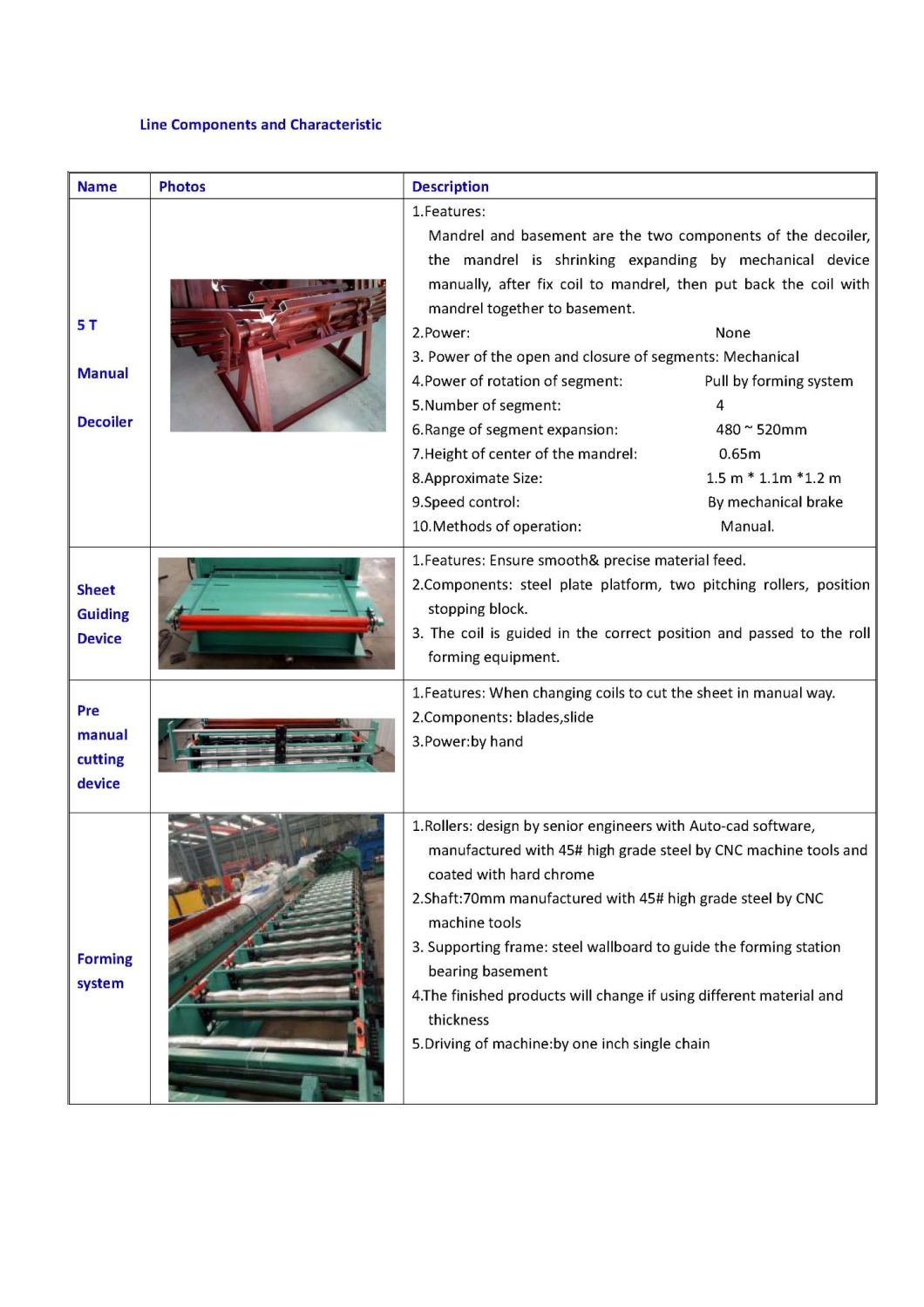

Trapezoidal and corrugated roof are used in common for construction.Roofing roll forming machineis designed to product iron roof sheet.It is composed of 5tons Manual Decoiler,material feeding device,main roll forming,and automatic cutting.It is formed from ppgi,color coated gavalume and aluminum etc.If you want to start the fabrication of roof,you can consider starting with the basic roof design.

Less Labor and Waste

(Run your panels to the exact length without time and material waste

Work On Your Own Schedule - Not The Factory's (When roof is ready -- just run your panels)

Complete photo o8. Profile Drawing

Complete photo o8. Profile Drawing

- Material:galvanized coil,color coated galvanized coil

- Thickness of material:03.-0.8mm

- 3)Yield strength of coil:250mpa,

- Working Flow& Layout

- 71f0f2180de6468e47a6565c03.png" title="profile sheet forming machine" alt="profile sheet forming machine" />

| NO. | Description | Quantity (set) | Remark |

| 1 | 7T Manual decoiler | 1 | |

| 2 | Guiding device | 1 | One complete unit as main machine |

| 3 | Forming system | 1 | |

| 4 | Transmission system | 1 | |

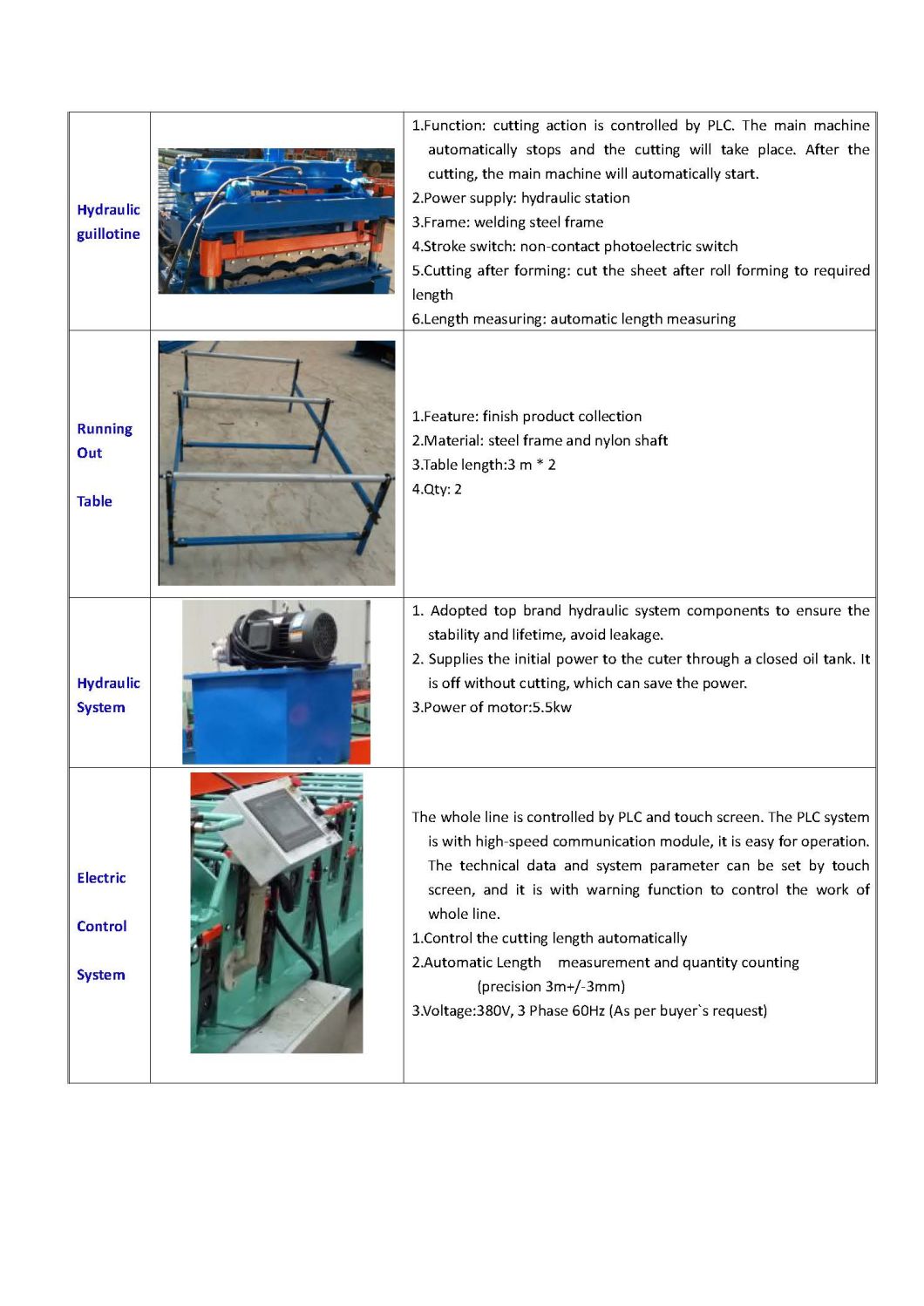

| 5 | Hydraulic guillotine | 2 | |

| 6 | Support table | 2 | |

| 7 | Hydraulic station | 1 | |

| 8 | Control box | 1 | |

| 9 | Manual collecting table | 2 | |

| 10 | Spare parts and tools | 1 | As attaching list |

| No | Item | Parameter | Note |

| 1 | Forming Speed | Max12-15m/min | Excludes cutting |

| 2 | Forming station | 16 or 13 groups | |

| 3 | Total Power | 5.5+4kw | |

| 4 | Total Weight | About 4200KGS | |

| 5 | Voltage | 380v,50hz,3p | |

| 6 | Diameter of shaft | 70mm | |

| 7 | Installation Size | 13 * 1.1 M*1.4 | |

| 8 | Sizes of chain | Double 0.6inch chain | |

| 9 | Thickness of wall structure | 18mm |

| No | Item | Parameter | Note |

| 1 | Forming Shaft | 45# steel with grinding process | |

| 2 | Forming Roller | 45# steel with tempering heat treatment and hard chrome coating | |

| 3 | Cutting Blade | Cr12 with hard treatment | |

| 4 | Control System | DELTA PLC& transducer, low voltage:SIEMENS. | |

| 5 | Electrical motor | From jiangsu | |

| 6 | Bearing | China quality brand | |

| 7 | Chain | China quality brand | |

| 8 | Hydraulic parts | China quality brand |

Looking for ideal Trapezoidal Roof Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Corrugated Roof Forming Machine are quality guaranteed. We are China Origin Factory of Roofing Sheets Making Machine. If you have any question, please feel free to contact us. Product Categories : Roof And Wall Panel Roll Forming Machine > Double Layer Roll Forming Machine

Looking for ideal Trapezoidal Roof Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Corrugated Roof Forming Machine are quality guaranteed. We are China Origin Factory of Roofing Sheets Making Machine. If you have any question, please feel free to contact us. Product Categories : Roof And Wall Panel Roll Forming Machine > Double Layer Roll Forming Machine