Basic Info

Model No.: carrying channel

Material To Roll Forming: Ppgi,gi,aluminum,alu-zinc

Thickness Of Material: 0.4-0.8mm

Main Power Of Motor: 7.5kw

Driving Of Machine: By Gear

Voltage Of Machine: 380v,50hz Or As Your Request

Diameter Of Shaft: 50mm

Structure Of Machine: Welded Box Structure

Color Of Machine: Blue Or As Your Request

Power Of Hydraulic Pump: 4kw

Additional Info

Packaging: standard packing

Productivity: 30sets/Month

Brand: ODM

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 30sets/Month

Certificate: CE

HS Code: 8455221000

Port: TIANJIN

Product Description

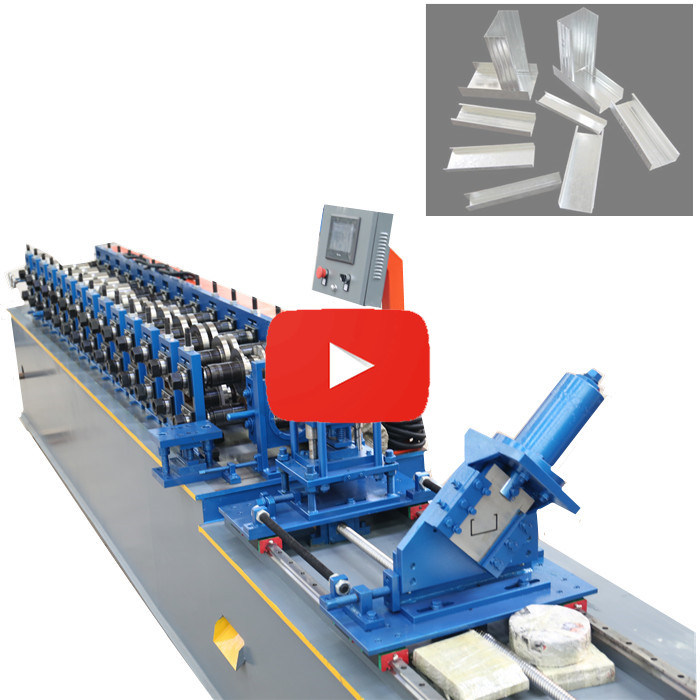

Carrying Channel Ceiling Roll Forming Machine

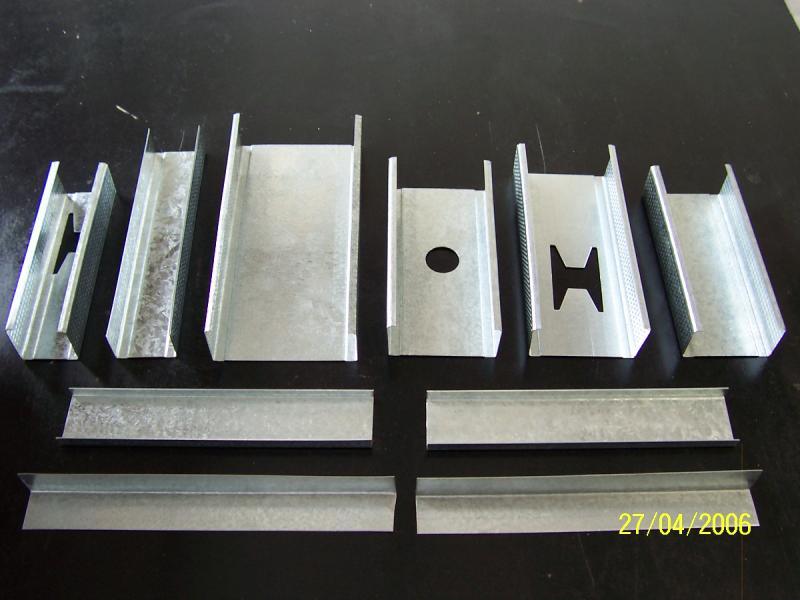

The Carrying Channel Roll Forming Machine has been designed for the manufacturing of c shaped channels used to build lightweight or light gauge ceilings.

Being one of the roll forming machines for the production of lightweight or light gauge steel frames, a carrying channel Roll Forming Machine or hat channel roll forming machine produces metal furring channels or hat channels continuously and automatically from galvanized steel of 0.6-1.2mm thickness as main components of steel roof trusses on lightweight or light gauge buildings.

Specialized manufactuerer of roll forming machine,framing machine,guardrail forming machine,different designs can be customized as your request.

| Technical parameters of ceiling roll forming machine: | |||||||

| 1 | Name of commodity & specification | Drywall Galvanized Sheet Light Steel Profiles Metal Stud/Track Roll Forming Machine ud cd uw cw profiles | |||||

| 2 | Main motor power | 4kw, 3 phase | |||||

| 3 | Hydraulic motor power | 3kw | |||||

| 4 | Hydraulic Pressure | 10-12MPa | |||||

| 5 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) | |||||

| 6 | Control System | PLC Delta Inverter | |||||

| 7 | Main Frame | welded steel plate | |||||

| 8 | Backboard Thickness | 20mm | |||||

| 9 | Driving of machine | gear box and chain driving | |||||

| 10 | Feeding Material | color steel coils | |||||

| 11 | Feeding Thickness | 0.3-1.2mm | |||||

| 12 | Feeding Width | 90 | |||||

| 13 | Effective width | according to your request | |||||

| 14 | Productivity | 0-25m/min | |||||

| 15 | Roll Station | 10 | |||||

| 16 | Roller Diameter | 50mm | |||||

| 17 | Roller material | 45# steel | |||||

| 18 | Cutter material | Cr12 , quenched | |||||

| 19 | Cr-Plating Size | 0.05mm | |||||

| 20 | Overall Size | 3600×900×1200mm | |||||

| 21 | Total Weight | 2.7T | |||||

| 22 | Components | Manual Uncoiler-------------------1 set Guiding Platform------------------1 set Coil Strip Leveler------------------1 set Main Machine of Roll Forming------1 set Electric-Motor---------------------1 set Cutting Device--------------------1 set Hydraulic Station------------------1 set PLC Control-----------------------1 set Supporter Table-------------------1 set | |||||

| 23 | Workflow | Manual decoiling----feeding and guiding----roll forming----cut to length----run out table | |||||

| 24 | Package | nude in the container | |||||

| 25 | Minimum order quantity | 1 set | |||||

| 26 | Payment terms | T/T(30% T/T pay in advance, the remaining 70% pay before ship) | |||||

| 27 | Delivery time | 30 working days later after receiving the deposit | |||||

| All technical parameters can be changed, according to user's need. | |||||||

Product Categories : Light Gauge Steel Framing Forming Machine > Drywall Partiton Profile Forming Machine