Cable tray roll forming machines are specialized pieces of equipment that are used to manufacture cable trays from raw materials such as steel, aluminum or other metals. These machines work by forming the metal sheets into the desired shape to make a continuous tray that is easy to install and maintain. The finished cable trays also come with various accessories including clamps, brackets, and bolts to ensure the trays are securely fixed in place.

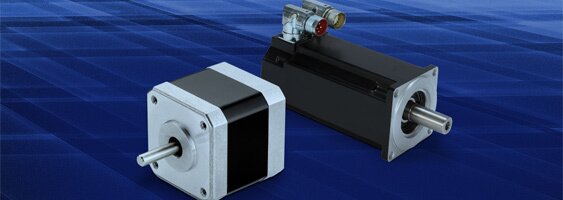

One of the critical features of cable tray roll forming machines is their servo guiding device. This advanced technology is a system that enables the machines to maintain high accuracy and consistency in the final product. The servo machine accurately adjusts to the metal specifications and adjusts the forming rollers as needed to produce quality cable tray products.

Another vital component of cable tray roll forming machines is the touch screen PLC control system. This state-of-the-art technology enables the machine operators to control all the aspects of the machine's operation through an easy-to-use interface. With the touch screen PLC control system, operators can set different parameters such as tray size, speed, and other features. They can also monitor the machine's performance in real-time, detect any issues, and perform maintenance tasks if needed.

Cable tray roll forming machines are available in different models and sizes depending on the needs of the user. Some machines are automatic and can produce hundreds of meters of cable tray per hour, while others are manual and require operators to feed the metal sheets into the machine. Automatic machines are often the preferred option, as they increase the production capacity and provide better accuracy and efficiency. Nonetheless, manual machines are still useful for small-scale operations or for producing customized trays tailored to customer requirements.

When it comes to cable tray roll forming machines, there are several manufacturers who produce high-quality equipment. However, Jiangyin Dingbo Technology CO., Ltd. (need remove brand name) stands out for their Touch Screen PLC Control Cable Tray Roll Forming Machine with Servo Guiding Device. This machine features an advanced control system that ensures precise and uniform product output. The machine also comes with a servo guiding device that maintains high accuracy in the finished product, a feature that is crucial in meeting the industry's quality standards.

In conclusion, cable tray roll forming machines have become an essential component of modern building construction projects. They help to produce high-quality cable trays that are durable, sturdy, and easy to install. With advanced features such as the touch screen PLC control system and servo guiding device, cable tray roll forming machines are becoming more efficient and effective in producing quality products.

If you're looking for a cable tray tile equipment, consider investing in a high-quality roll forming machine. Look for a reputable manufacturer who can provide you with the most advanced and efficient equipment that meets your specific requirements. With the right machine, you can be sure of producing quality cable trays that meet the highest Industry standards.